How do I Choose LED High Bay Lights?

When choosing LED high bay lights, focus on lumens rather than wattage. As LED technology improves, wattage decreases while maintaining high efficiency. Match the lumen output to the installation height for optimal lighting:

- 12–16 feet: Suitable for 12,000–15,000 lumens (80W–100W at 150 lm/W efficiency).

- 18–23 feet: Suitable for 16,000–23,000 lumens (120W–150W at 150 lm/W efficiency).

- 25–35 feet: Suitable for 25,000–36,000 lumens (160W–240W at 150 lm/W efficiency).

Proper lumen selection ensures adequate brightness for various ceiling heights.

What are LED High Bay Lights?

LED High Bay Lights are designed for spaces with high ceilings, where traditional lighting options fail to perform efficiently.

LED High Bay Lights are powerful lighting solutions that provide uniform and bright illumination for spaces with ceilings above 20 feet, such as warehouses, factories, and gyms.1

These lights are widely used in industrial, commercial, and retail applications due to their superior efficiency and performance.

Key Features of LED High Bay Lights

- Bright and Uniform Lighting: LEDs eliminate dark spots, ensuring consistent brightness across large areas.

- Energy Efficiency: LEDs use less energy compared to traditional lights, reducing electricity costs.

- Durability: With a lifespan of over 50,000 hours, LEDs require minimal maintenance.

| Feature | Benefit |

|---|---|

| High Brightness | Better visibility |

| Long Lifespan | Reduced maintenance costs |

| Energy Efficiency | Lower operational expenses |

Why LEDs for High Bay Lights?

Traditional lights like metal halide or fluorescent lamps are less efficient and have shorter lifespans. LEDs outperform them in every way.

LEDs are ideal for high bay lights because they offer better energy efficiency, longer lifespans, and superior lighting quality compared to traditional options.

Advantages of LEDs for High Bay Lights

- Energy Savings: LEDs convert energy into light, minimizing wastage.

- Maintenance-Free: With a long lifespan, LEDs reduce replacement costs.

- Eco-Friendly: LEDs are recyclable and free of hazardous substances like mercury.

| Lighting Type | Energy Usage (Watts) | Lifespan (Hours) |

|---|---|---|

| Incandescent Bulbs | 300-500 | 1,000 |

| Metal Halide Lamps | 250-400 | 15,000 |

| LED High Bay Lights | 95-240 | 50,000+ |

Real-Life Impact

Switching from metal halide to LED High Bay Lights can reduce energy costs by 60-70%. A client of mine reported a significant drop in maintenance disruptions after upgrading their warehouse lights.

Which we should consider when choosing LED High Bay Lights?

The market is filled with options, and choosing without proper understanding can lead to inefficiencies.

Consider ceiling height, required lumens, beam angle, and color temperature to ensure your LED High Bay Lights meet the specific needs of your space.

Critical Factors to Evaluate

Ceiling Height and Beam Angle

The height of your ceiling determines the appropriate beam angle. Higher ceilings require narrow beams for focused lighting, while lower ceilings benefit from wide beams for broader coverage.

Brightness (Lumens)

Instead of focusing on wattage, prioritize lumens, which measure the actual brightness of the light. Higher lumens per watt indicate better efficiency.

| Ceiling Height (Feet) | Recommended Lumens | Beam Angle |

|---|---|---|

| 15-20 | 10,000-15,000 | Wide (120°) |

| 20-30 | 15,000-30,000 | Medium (90°) |

| 30+ | 30,000+ | Narrow (60°) |

Color Temperature

Choose the appropriate color temperature based on the application.

- Cool White (5000K): Ideal for industrial spaces requiring clarity.

- Warm White (3000K): Better for retail settings to create a welcoming atmosphere.

Additional Features

- Dimmable Options: For customizable brightness and energy savings.

- IP Ratings: Ensure water and dust resistance for harsh environments.

- Motion Sensors: Automatically control lighting for efficiency.

How many LED High Bay Lights are required?

Proper planning ensures adequate illumination without over- or under-lighting your space.

To determine the number of LED High Bay Lights needed, calculate the area size, lumens per square foot, and the output of each fixture.

Calculation Steps

- Measure the Area: Determine the total square footage of the space.

- Determine Required Lumens: Multiply the area by lumens per square foot (typically 30-50 for industrial spaces).

- Choose Beam Angle: Match it to your ceiling height.

- Calculate Quantity: Divide total required lumens by the lumen output of a single fixture.

Example Calculation

For a 10,000 sq. ft. warehouse with 20-foot ceilings:

- Lumens needed: 10,000 sq. ft. × 30 lumens/sq. ft. = 300,000 lumens

- Using fixtures with 15,000 lumens each: 300,000 ÷ 15,000 = 20 lights required

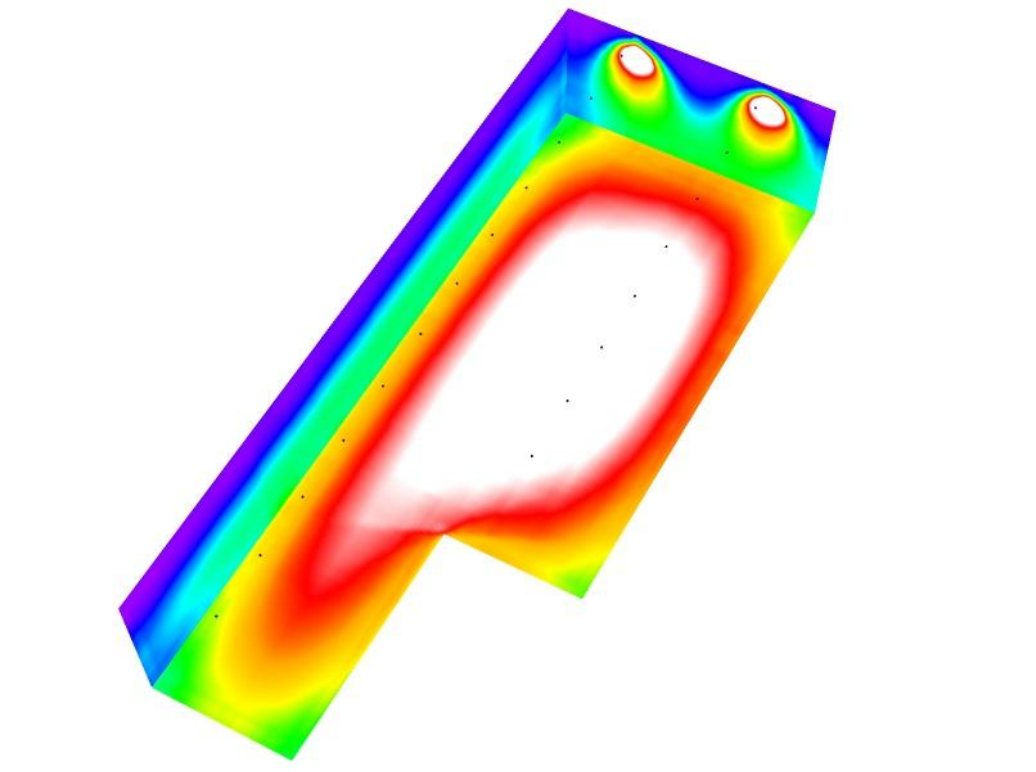

Layout and Spacing

Proper spacing ensures even light distribution. Avoid overlapping beams or leaving dark spots. Consult manufacturers for layout simulations to optimize placement.

Conclusion

Choosing the right LED High Bay Lights requires understanding their features, evaluating your space's needs, and calculating the number of fixtures. With proper planning, you can achieve energy-efficient and effective lighting for any high-ceiling space.

-

Understand why LEDs are ideal for spaces with ceilings over 20 feet. ↩